- Group home

- You must register/login in order to post into this group.

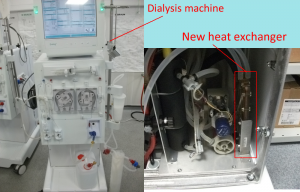

Retrofit of Heat Exchangers to Dialysis Machines

By: Newcastle Upon Tyne Hospitals NHS Foundation Trust

Reduced electricity bills for home dialysis patients

£327.60 - but likely to increase in Winter (Estimated)

1.207 tonnes - but likely to increase in Winter (Estimated)

Heat exchangers have been retrofitted to all 21 BBraun Dialog+ Dialysis Machines for patients on home haemodialysis. The decision was taken to prioritise retrofit of home haemodialysis machines after analysis of temperature changes and power consumption in the home and dialysis unit settings. The colder incoming water in patients' homes in Winter, as compared with the water temperature in the dialysis centre, resulted in increased power consumption over all and greater energysavings from inclusion of the heat exchanger.

Benefits to environmental sustainability

Estimated energy/CO2 savings

Energy savings were estimated by comparing a standard cycle on a machine with heat exchanger to one without. Results in the dialysis unit showed 5.2 kWh vs. 4.7 kWh (with heat exchanger), a saving of 0.5 kWh per treatment, or approx. 10%.

However, electricity usage was almost 3x higher for a treatment at the home of a home-dialysing patient, where the incoming water temperature was 5C, as compared with 10-22C in the dialysis unit. Power consumption from the WRO and HD without heat exchanger was 14.05 kWh. Energy savings in this setting would be expected to be greater. Even a 10% saving would save 1.4kWh per treatment – 218.4kWh per year.

Actual savings to date

Initial recordings have been taken in the summer months with an incoming water temperature of approx. 18C. Under these conditions, retrofitting of the heat exchangers has reduced electricity consumption by 0.625kWh per treatment. For a typical patient on 3 treatments per week, if the energy saving remained constant, then total energy savings would be 0.625kWh x 3 x52 = 97.5 kWh. Carbon savings would be estimated as 97.5 x 0.58982* = 57.5 kg CO2e per year per machine, or 1.207 tonnes CO2e for all 21 machines.

However, energy savings are likely to increase in winter with lower water temperatures in patients' homes.

Additional Benefits

The 21 home dialysis patients will benefit from reduced electricity bills. This cost saving may in future be passed onto the renal service through a commensurate reduction in the financial support given towards patients' utility bills. At a standard domestic tariff of £0.16/kWh, the 0.625 kWh electricity saving equates to a cost saving of approx. 10p/ treatment, translating to £15.60/year per machine, or £327.60/year for all 21 machines. However, total energy consumption and energy savings from the heat exchangers are expected to increase in colder weather.

* GHG emission factor for electricity consumed (2010 grid rolling average), taken from 2012 Guidelines to Defra / DECC's GHG Conversion Factors for Company Reporting (Table 3c)

Details of Implementation

Following contact from the Green Nephrology programme, highlighting environmental and cost savings achieved by retrofit of heat exchangers in Kent, Dr Suren Kanagasundaram (Renal Consultant and Newcastle Green Nephrology Local Representative) asked the renal technicians to investigate the business case for retrofitting heat exchangers locally.

45 machines were found to be suitable for retrofit. Because of the greater energy savings in the home setting and the availability of funding via the home dialysis conversion budget, the decision was taken to prioritise retrofit of all 21 home machines.

The cost (approx. £4,700 (£223.70 per machine, including £7.50 labour costs)) was found from the home dialysis conversion budget.

Electricity energy saving in patients homes – with both environmental and financial benefits.

The project was shortlisted for the Green Nephrology Awards 2012. The PDF award entry poster may be downloaded from here.